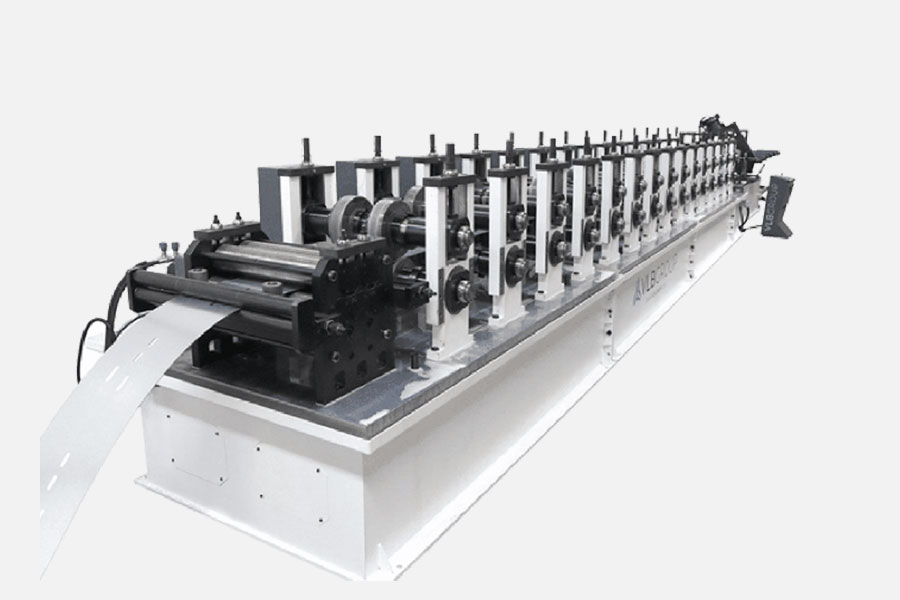

A roll forming line is a continuous metal forming process that gradually shapes metal coils into desired profiles through a series of precisely aligned rollers. This automated process ensures high efficiency, consistency, and precision, making it ideal for producing long, uniform components used in industries such as construction, automotive, and infrastructure.

Key Features

- Continuous & High-Speed Production – Enables efficient mass production with minimal downtime.

- Consistent & Precise Forming – Maintains uniformity and accuracy in profile dimensions.

- Versatile Material Compatibility – Works with steel, aluminum, copper, and other metals.

- Customizable Profiles – Supports a variety of shapes, including channels, tubes, and beams.

- Minimal Material Waste – Optimized forming process reduces scrap and enhances cost efficiency.

- High Structural Integrity – Produces strong, lightweight components with excellent durability.

- Automated Operation – CNC and PLC control ensure repeatability and ease of operation.

- Integrated Cutting & Punching – In-line processes for precise cutting, perforation, and embossing.

- Energy Efficient & Low Maintenance – Reduces operational costs with optimized power usage.

- Wide Industrial Applications – Used in roofing sheets, automotive panels, metal furniture, and more.