Cable Tray Manufacturers in Pune - 2026

V P Industries is well known Cable Tray Manufacturers in Pune, Suppliers, Dealers and Exporters in Pune. Our cable trays are designed and made of high quality to provide long durability, high load carrying capacity and easy installation. Our products are structured to work in and serve various industrial, commercial and utility settings in precision and reliability. Our cable tray systems promote safety, ease routing and reliable support of any endeavour as we are very keen on quality, innovation and compliance.

What is a Cable Tray?

It is an organized housing that is used to carry and handle electrical and communication cables in a safe manner. It makes the wiring system tidy, minimizes the number of wires, and makes them accessible to installation and maintenance. Cable Trays in Pune are also popular in the industrial, commercial, and infrastructure works to manage cables effectively.

Types of Cable Tray

As well known Cable Tray Manufacturers in Pune, we offer a variety of trays for organized and safe cable management.

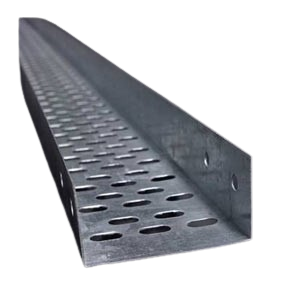

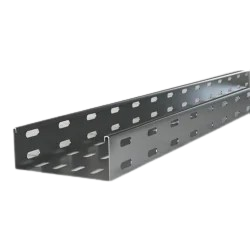

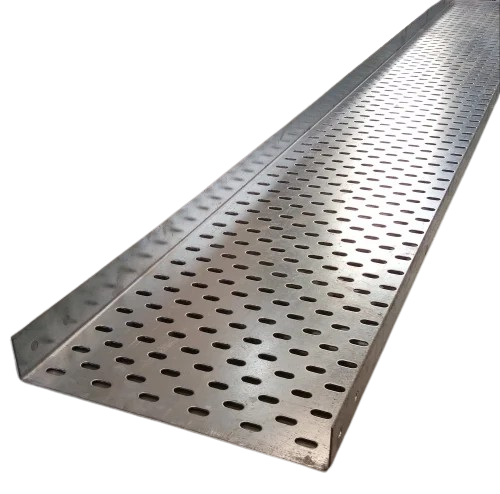

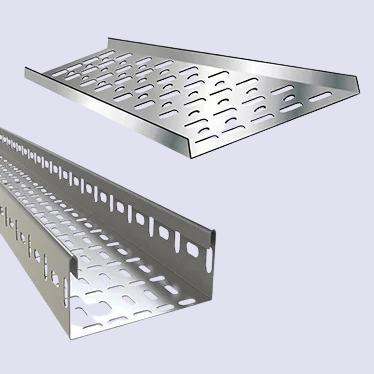

- Perforated Cable Trays: These trays have many holes that increase a ventilating action and avoid cooling of cables. They are suited in the indoor electrical and industrial wiring systems where there is a lot of air flow and convenient maintenance of wires.

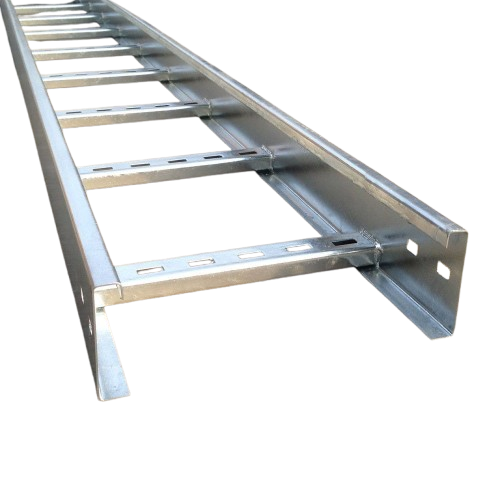

- Ladder Cable Trays: These rails are provided with side rails and rungs which are very strong in supporting heavy cable loads. Their open design permits maximum heat removal and hence, is ideal with large installations in industries.

- Powder Coated Cable Tray: These trays have a durable powder layer which is resistant to corrosion, abrasion and harsh chemicals. They are perfect to be used over a long period in an environment that needs a smooth, protective, and rust free coating.

- Hot Dip Galvanized Cable Tray: The HDG trays are coated with a coating of thick zinc which provides good resistance to corrosion. Galvanized Cable Trays in Pune would work very well in moist, wet and industrial climate where there is exposure to moisture and chemicals.

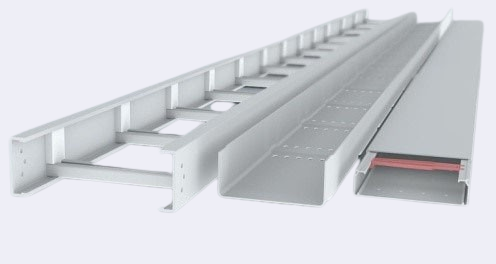

- Raceway Cable Tray: These are completely airtight and they ensure that the cables are not exposed to dust, dirt and external factors. The closed design suits best cleanrooms, laboratories, IT aggregates, and data environments that are sensitive.

- FRP Cable Tray: They are constructed by way of Fibre Reinforced Plastic which is highly strong, fire resistant and non-conductive. They are perfectly suited to the use in the corrosive and harsh industrial environments where metal trays can degrade.

- Stainless Steel Cable Trays: The trays have a great resistance to corrosion, heat and chemicals. Their hygienic clean and smooth, surface makes them an ideal choice in food processing, pharmaceutical, as well as cleanroom needs.

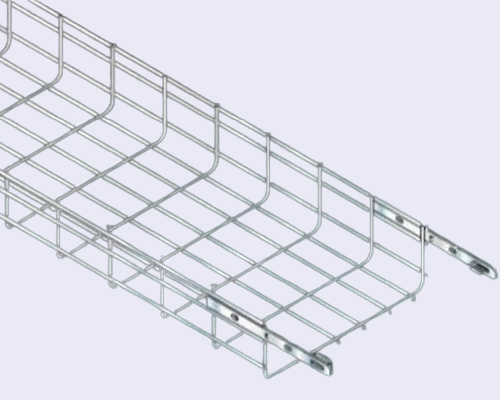

- Wire Mesh Cable Tray: It offers flexible and lightweight cable support with better ventilation. They are common in telecom installations, data centres and IT networks as they are simple to install and they are accessible.

- Electrical Cable Tray: These trays are produced with the purpose of organizing and segregation of electrical wiring. They provide protection in routing high voltage cables and lower risks and system reliability.

- Solid Bottom Cable Tray: They are completely sealed at the base and are thus fully dustproof, waterproof and descending debris proof. They are perfect during sensitive or delicate cables in a harsh environment.

- Channel Type Cable Tray: They are designed in shape of U that ensures that cables are well contained along a specified route. They are applicable in both smaller cable routing and installation where smaller routing is needed.

Cable Tray Manufacturers in Pune.

Technical Specifications of Cable Tray

As Cable Tray Suppliers in Pune, we have added below a sheet of technical details for cable trays.

| Feature | Details |

|---|---|

| Material | Galvanized Steel (GI), Stainless Steel (SS), Aluminium, FRP (Fiber Reinforced Plastic) |

| Width | 50 mm to 1000 mm |

| Height (Depth) | 25 mm to 150 mm |

| Thickness | 1.2 mm, 1.6 mm, 2.0 mm, 2.5 mm, 3.0 mm |

| Length | 2500 mm to 3000 mm per piece |

| Type of Tray | Ladder Type, Perforated Type, Solid Bottom, Wire Mesh, Raceway |

| Finish | Hot-Dip Galvanized, Pre-Galvanized, Powder Coated, Painted |

| Load-Bearing Capacity | Light Duty, Medium Duty, Heavy Duty |

| Ventilation | Open (Ladder / Perforated), Enclosed (Solid Bottom) |

| Perforation Size | 10×20 mm, 15×25 mm (varies by model) |

| Rung Spacing | 150 mm to 300 mm (ladder type) |

| Standards Compliance | IEC 61537, NEMA VE 1, IS 8623, ASTM A123, BS EN 61537 |

Benefits of Cable Tray

As trusted Cable Tray Dealers in Pune, we offer trays that ensure efficient load distribution, durability under heavy cables, and protection against environmental hazards.

- Enhanced Cable Safety: PVC Cable Tray protect cables against dust, moisture and physical damages and minimize chances of short circuit or insulation breakdown whilst providing secure routing in challenging conditions.

- Superior Cable Organization: Gi Cable Trays maintain the wiring in orderly conditions to avoid a mess. This structured design increases clarity of the systems, eases troubleshooting and installation are much easier.

- Efficient Heat Dissipation: Perforated and open designs provide a natural airflow around cables and eliminate overheating, maintain steady performance and increase cable life.

- Cost-Effective Installation: Compared to conduits, cable trays are made of fewer materials and less labour is required. Their modular structure reduces the time of installation and minimizes the total project.

- Scalability and Easy Maintenance: The cables are also left in sight and are easily accessed, enabling one to easily check, repair or upgrade them. It is also easy to scale up the system to meet the future needs.

Applications of Cable Tray

As we are leading Cable Tray Exporters in Pune, our products are ideal for data centres, electrical substations, factories, and automation systems.

- Energy Facilities and Power Plants: Large installations have high-voltage, control, and instrumentation cables which they carry. They have high load bearing capacity and heat resistance making them operate well and long.

- Oil & Gas Industry: Trinity Touch Cable Tray handles power and communication cables of corrosive and moisture-heavy conditions. They have long lasting, corrosion resistant materials which provide good performance in offshore and refinery conditions.

- Manufacturing & Heavy Industries: They plan power and automation wiring on production lines. Their modular structure enables fast changes when there are alterations in the layouts of machinery or processes.

- Chemical and Petrochemical Plants: They cover instrumentation cables and control cables against vapours and high temperatures. They are toughly constructed and therefore remain stable in aggressive industrial conditions.

- Mining and Material Handling Facilities: They advocate lengthy cable pathways of conveyors, crushers and heavy apparatus. Their rough structure is resistant to dust, vibration and high mechanical pressure in mining activities.

Why Choose Us?

- Reliable and Quality Systems: Our cable trays are fabricated using GI, SS, aluminium and FRP which means that the product will perform long with withstand any corrosion under any condition.

- Safe and Organized Cable Management.: Cable Tray dealers in Pune come up with trays that cover, secure cables, and avert overheating besides making work easier and safer through maintenance.

- Adaptable and Tailored Solutions: Cable Tray suppliers in Pune provide off-the-shelf, scalable systems that can be customized to meet project requirements and easily expanded, re-routed or upgraded without interruption.

V P Industries is the reliable Cable Tray Manufacturers in Pune, Suppliers, Dealers and Exporters in Pune. Our products are industrial, commercial and infrastructure cable tray solutions, of high quality and durability. To guarantee efficient and durable installations, we put emphasis on safety, orderly cable management, and flexible and scalable designs of the installations. We have experience and high quality materials to help in planning and implementing all the projects and produce cable tray systems that are easy to maintain and control performances and are also reliable in meeting the needs of various settings. Connect with us to get best solutions.

A cable tray is a mechanical support system for electrical cables, used as an alternative to open wiring or conduits in industrial and commercial buildings.

The three main types of cable trays commonly used in electrical installations are: Ladder Type Cable Tray, Solid bottom Cable Tray, Perforated Cable Tray

Cable trays are used in a wide variety of settings, from industrial plants and commercial buildings to hospitals and data centers, to safely and efficiently manage and support electrical and communication cables.

Related Searches :

Cable Tray Manufacturers in Pune, Cable Tray Suppliers in Pune, Cable Tray Manufacturers in Chakan, Cable Tray Suppliers in Chakan, Cable Tray Manufacturers in Bhosari, Cable Tray Suppliers in Bhosari, Cable Tray Manufacturers in Katraj, Cable Tray Manufacturers in Ranjangaon, Cable Tray Suppliers in Ranjangaon, Cable Tray Manufacturers in Shirwal, Cable Tray Manufacturers in Pirangut, Cable Tray Manufacturers in Shikrapur, Cable Tray Manufacturers in Wagoli, Cable Tray Manufacturers in Wakad, Cable Tray Manufacturers in Baner, Cable Tray Manufacturers in Chinchwad, Cable Tray Manufacturers in Hadapsar, Cable Tray Manufacturers in Swargate, Cable Tray Manufacturers in Baner.